Service & Frequently Asked Questions

Before Production

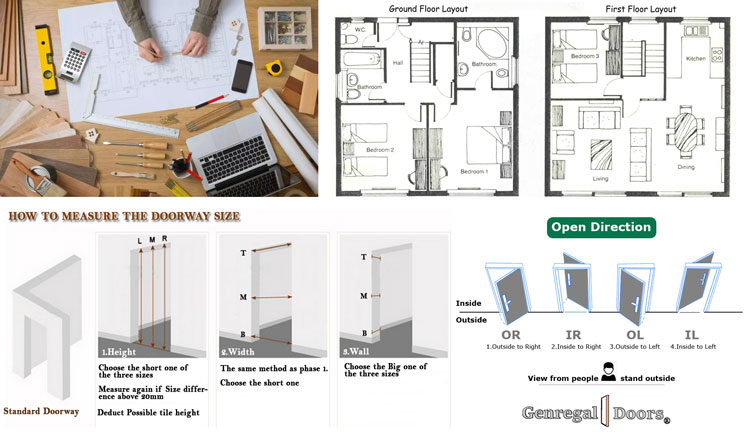

The buyer needs to firstly provide the size of the wall holes for the doors, then choose the style and material & quantity, collect to BOQ list. we will communicate and check with the buyer through graphic form according to the information provided by the buyer and summarize the detailed requirements. After the buyer accepts the production delivery time and payment terms, we will sign the contract, collect the advance payment and carry out the preparation and production of the specified doors.

Usually the buyer selects a door, taking into account the local climate, local habits of use, and reference to the designer. Different door materials have different properties for fireproofing, waterproofing, soundproofing, anti-rust and anti-deformation. Some buyers would like to add acoustic wool into interior doors to improve the soundproof performance in bedrooms. some buyers would like to add solid wood trim decorations on the surface of fire-rated doors to enhance the decorative effect in hotels, and some buyers would install water-proof doors with higher specifications of rust-resistant handles separately. We will listen to the buyer’s needs and provide personalized solutions.

Yes, it is a common practice to pre-hung wood door panel on steel or aluminum frame. The purpose is usually to make installation and removal easier, and in some cases where the door needs to be fire rated function, steel frames are more conducive to flame stopping than wood frames, and maintain the decorative effect that wood door panels provide. Another advantage of steel frame is that they are narrower, which makes it easier to load they into the container in a smaller package after it has been pre-assembled.

A pre-hung door is a door set that has already been installed on frame with hinges during the manufacturing process. When these doors are transported to the site, a few expansion screws to the wall would complete the installation, which is very convenient. steel doors and aluminium doors are commonly of this type, while wood door, because of its thicker frame should cover the wide wall, pre-hung it might safe and would lead to large unit volume. wooden door and frame therefore is not pre-installed in most cases, they will be in separate packagings.

Surface treatment refers to the production process in which doors are finally textured and coloured and effected according to different materials. Usually, the surface treatment process of the painted and plated types is complicated, the production time is longer, the requirements for dust-free production are higher, the finished products of them get more durable and richly saturated colours. The paintless types’ process is quicker, requires no subsequent drying after laminating. After several generations of updating, paintless pre-finished colour layers can also achieve simulated effect and high-grade effects, and most importantly, it allows for lower overall budget of project.

Special function usually refers to the door with fireproof, waterproof, anti-prying, ventilation, automatic opening and closing, automatic dust stopping etc. Some functions need to change the door’s infilling and frame material, other functions need to install specific accessories onto the doors. when we receive the specific needs from buyer, we will provide the corresponding pictures for the buyer to quickly decide and work out solutions.

Wood doors are usually more suitable for sliding, folding and revolving doors than steel doors. This is because wooden doors can be readily fitted with slots and screws for different functions. If the steel door to achieve these functions, the slots need to be pre-worked on the steel panel in the early stage of production, if there is no ready-made mold, usually the size of the slot is not accurate, we need to make new mold before we can press the slots for the new accessories.

Yes, we support our customers to provide their own personalised locks and send sample to us to open holes on their doors.

After Production and Delivery

Usually steel Door and melamine wood door 25-28days to finish production of quantity within 1000pcs , Painting wood door and Fire rated door 32-38days to finish production of quantity within 1000pcs, painting and dry faster in Summer.

Normally for wood door standard size 2100x800mm and frame, 20ft container= 170 pcs,40hq container =370pcs . Steel door standard size 2050x950mm 20ft container= 125pcs,40hq container =280pcs.

When buyer purchase doors’ quantity of full 20ft and 40HQ,the average transporting cost to our nearest port for each door is lower. The unit door FOB price is close to bulk order price.

On the other hand, if buy samples or quantity like 5-15 pcs (LCL order) quantity less than 100pcs, the average transporting cost to port would be higher than full container’s delivery, therefore the LCL unit FOB price would be adjusted according to actual inland transportation cost on the day of shipment.

Got Your Answer?

If you haven’t found answer on above FAQs, please feel free to contact us directly with any questions you may have about our products.